Project Second Week Progress Report¶

Week Period: November 10, 2025 - November 14, 2025

Progress Report¶

During this period, the project team strictly adhered to the established execution plan, efficiently advanced various core tasks, and successfully over-achieved the phase objectives. The specific progress is as follows:

Rocket Main Structure Fabrication¶

In the rocket main structure fabrication phase, the team focused on the core 3D printing process, executing precisely according to the preset technical parameters and structural design scheme. Before printing, consumable performance testing, equipment accuracy calibration, and layered slicing parameter optimization were completed. During the printing process, the forming quality was controlled through a real-time monitoring system, promptly avoiding potential issues such as weak interlayer bonding and dimensional deviations. After several consecutive days of standardized operation, key structural components including the rocket body, fins, and fairing were successfully printed and formed. Through 3D scanning inspection, the dimensional tolerance of each component was controlled within ±0.1mm. Indicators such as structural strength and surface smoothness all met the design standards. The core manufacturing objectives for the first phase were successfully achieved, completed one week ahead of the original schedule, thereby reserving sufficient time for subsequent processes.

Phase Two Work Deployment¶

Following the conclusion of the first phase tasks, the team promptly initiated the deployment of the second phase work, officially entering the rocket assembly and preliminary testing stage. The standardized layout of the assembly area has been completed, including setting up anti-static workbenches, calibrating professional tools like torque wrenches, and delineating component placement and operation areas to ensure a standardized and orderly assembly process. Concurrently, technical briefings were conducted regarding the assembly logic and connection methods for the various rocket structural components, clarifying key operational points such as bolt fastening torque and sealing treatment requirements. Currently, the preliminary docking of the rocket body and fins has been completed, and the adaptation and installation of the fairing to the rocket body are underway. The simultaneous preliminary testing work focuses on inspecting the accuracy of the structural assembly, using methods like laser distance measurement and angle measurement to verify the accuracy of each component's assembly position, laying the foundation for subsequent system integration.

Procurement¶

Regarding procurement, the selection and procurement process for core equipment required for the second phase and subsequent tests has been completed. After multiple rounds of supplier qualification review, product performance comparison, and technical parameter confirmation, suppliers for the rocket engine and high-definition camera that meet the project requirements were finally selected, and procurement contracts have been signed. The selected engine offers the technical advantages of stable thrust and rapid response, matching the load and flight performance requirements of this project's rocket. The camera selection emphasized high-definition image quality, anti-vibration and stabilization capabilities, and adaptability to harsh environments, meeting the requirements for real-time image capture and data recording during flight. Payment has been processed, and the suppliers are currently handling inventory preparation and shipping according to the agreement. The equipment is expected to be delivered by early next week for acceptance inspection.

Next Steps¶

Hereafter, the team will continue to advance the rocket assembly work, refining the assembly process to ensure reliable connections of all systems. Simultaneously, preparations for the engine installation and debugging plan are underway. Integration testing will commence promptly upon the arrival of the equipment, ensuring the project advances steadily according to plan.

Daily Progress¶

November 10, 2025¶

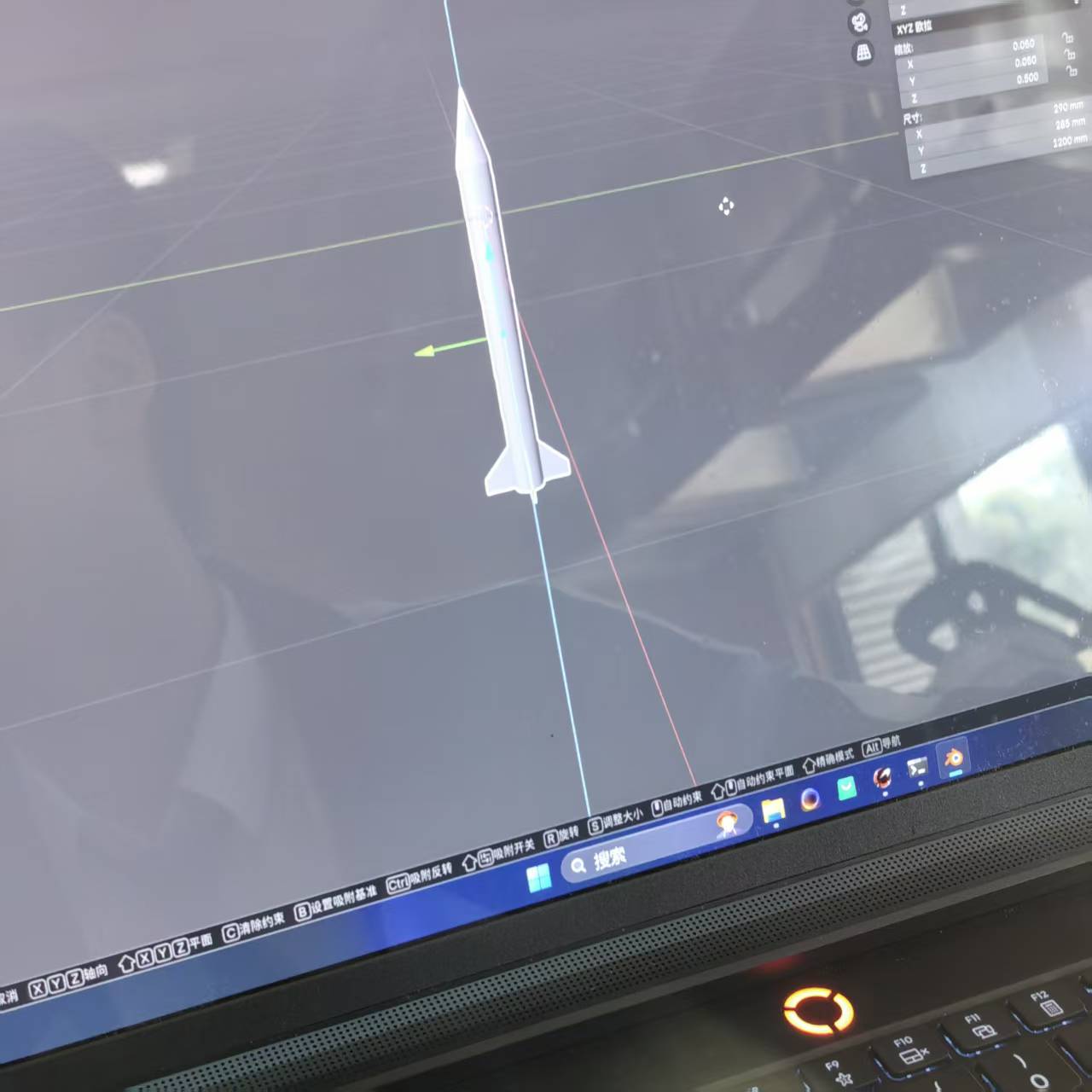

- Main Tasks Completed: Finalized the 3D model design of the rocket and officially initiated the printing and preliminary assembly process for various components.

- Detailed Progress: Today marks the official transition of the project from the design phase to the physical manufacturing stage. The team conducted final optimizations and confirmations on the rocket's overall structure, aerodynamic profile, and internal component layout. The first batch of structural components is scheduled to begin 3D printing.

- Next Steps: The printing of the main components is expected to be completed within the next two weeks, followed by systematic ground assembly and electronic component testing.